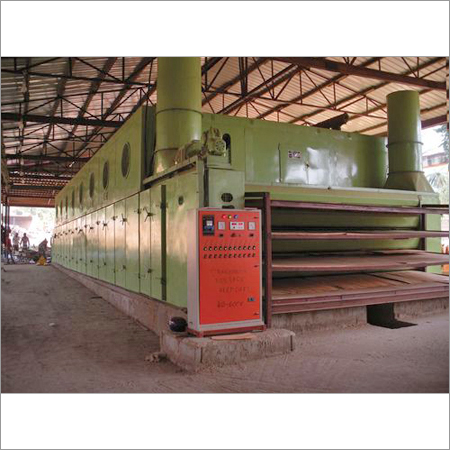

Roller Dryer Machine

Product Details:

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Warranty 1 Year

- Usage/Applications Industrial

- Click to View more

Roller Dryer Machine Price And Quantity

- 1 Piece

Roller Dryer Machine Product Specifications

- 1 Year

- Industrial

- Electricity

- Automatic

- Painted

Roller Dryer Machine Trade Information

- Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque Cash Advance (CA)

- Per Month

- Months

- WOODEN BOX

- Middle East Australia Eastern Europe Africa Central America Western Europe Asia North America

- All India

- ISO

Product Description

Roller Jet Dryer: 8 Section 4 Deck, 4od X 15-2 Long Roller:1no

Latest & Economical Type, Maintenance Free & Energy Saving

8 Section 4 Deck Roller Veneer Jet Dryer Of Steam / Thermic Fluid Oil Heating

Specification: One No. Heavy Duty, Latest & Special Type 8 Section 4 Deck Energy Saving Roller Veneer Jet Dryer Machine Will Have Jet Ventilated Roller Conveyor (Each Roller 4620 Mm Long & 110mm Dia), 16000 Mm (2000 Mm Of Each Section) In Ventilated Length, 3200 Mm Height, Having 8 Nos. Compact Drying Chambers (partition In Each Chamber) With 4 Decks, 1900 Mm Single Roller (3dia) Veneer Feeding Conveyor For Each Deck And 1300 Mm Long Cooling Section. The Dryer Is Fitted With Aluminium Propellers Having 4 Sets (each Set Of Two) Of Double Jet Nozzles For Top & Bottom Of Each Deck Throughout The Length Of The Dryer, 16000 Mm Heating Zone. The Machine Is Complete With Thermic Fluid/Steam Heating Coils, Top Dampers, Motors, Starters, Dynodrive (Infinitely Variable Speed Unit), Digital Temperature Indicator, Transmission Chain & Gear Box. The Entire Outside Covering Of The Dryer Is Perfectly Sheet Metal Body Insulated Seal & Top Covers With Heat Resisting Insulated Layer Of 100mm Thick All Round.The Following Motors Will Be Supplied By Us :-

-

8 Nos. 5 Hp, 960 Rpm, Ac, 440 V For Aluminium Fans

-

2 Nos. 1.5 Hp, 960 Rpm, Ac, 440 V For Cooling Section

- 1 No. 7.5 Hp, 1440 Rpm, Ac, 440 V For Dynodrive/Ac Drive Total Power 50.5 Hp

FAQs:

Q: What is a roller dryer machine?

A: A roller dryer machine is a large industrial machine that uses a series of heated rollers to dry materials as they pass through the machine. The rollers are usually made of metal and are heated by steam, electricity, or gas.

Q: How does a roller dryer machine work?

A: A roller dryer machine works by passing the material to be dried through a series of heated rollers. The rollers apply pressure to the material as it passes through, which helps to remove moisture and dry the material. The temperature of the rollers is carefully controlled to ensure that the material is dried evenly and without damage.

Q: What are the advantages of using a roller dryer machine?

A: Roller dryer machines offer a number of advantages over other types of drying equipment. They are fast, efficient, and can dry materials in a continuous process, which helps to increase productivity and reduce labor costs. They are also highly customizable, allowing for precise control over the drying process.